In 2006, three students from TU Delft started working with Taniq. Sören Blomaard was there from the start. He looks back on the early years and the success now: ‘What we offer makes sense, now we’re getting to work on great projects too.’

‘At that time, we were working on a study assignment that involved investigating whether you could commercialise a university patent’, Blomaard explains. ‘We investigated whether a composite technology from the aerospace industry had possible applications in other sectors. First of all, we approached companies in the offshore and automotive industries, among others, to find out if they were interested in this innovation. The standard approach is to design something first and then hit the road with it. But we entered into discussions with the end users first, also on the advice of the tech incubator YesDelft.’

A change of direction

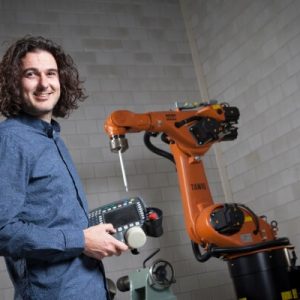

In those early years, Blomaard and his partners realised that their original approach to licensing wasn’t working. ‘We wanted to license our technology to manufacturers. But we soon discovered that producers didn’t have the machines and knowledge to use our technology. So we developed user-friendly software to make this knowledge available, as well as robots, which enabled us to automate large parts of the process. Ultimately, we deliver everything turnkey, including customised software and the training of employees to operate the robots.’ The possibilities offered by an in-house finite element analysis (FEA) model assist this process: ‘This enables us to test a digital prototype in all sorts of load conditions. This means that we don’t have to make as many expensive, physical prototypes. This saves all parties time and a lot of money.’

A focus on innovation

One of the best projects from the past years was a robot designed to make large fibre-reinforced rubber hoses up to 1.5 metres in diameter for the dredging and mining industries. This is traditionally a highly manual and work-intensive process that’s often outsourced to Asia. Taniq designed software and a robot to automate the concept and design process. Blomaard explains, ‘Our robot is up to 80% faster and always delivers the same high quality. This allows us to provide Western manufacturers with a solution to manufacture their products locally (again).’ Everything patented? ‘In some instances, we don’t patent an invention. In those cases, it’s so well hidden in the process that we make a conscious decision not to make it public. In other instances, we work together with V.O. They know how you can get good cover for your patent and how to write it down.’ Blomaard is still enthusiastic about Taniq: ‘What we offer makes sense, and means that we get to work on great projects too.’