‘Trademark advice, monitoring and protection is one at V.O. That is logical and pleasant.’

The company is the only Delft-based remaining producer of Delft Blue since the 17th century. It began in 1653 with the establishment of earthenware factory 'De Porceleyne Fles' and today Royal Delft still produces Delft Blue according to the authentic method. Its brand has grown over the years into a luxury brand.

Tradition and innovation

In terms of manufacturing, Royal Delft is primarily focused on maintaining and further developing the centuries-old craft and thus the cultural heritage of the Netherlands. Henk Schouten, CEO of Royal Delft: "On the one hand, we tell a historical story to our visitors in our museum and we produce authentic Delft Blue. On the other hand, we also create new designs for exclusive collections that also unmistakably bear Royal Delft's own stamp. We are thus developing more towards a premium brand. In doing so, we seek cooperation with renowned, international brands in other industries; for example, luxury fashion labels and interior design brands. In doing so, we want to appeal to a new audience and thus increase our familiarity and make the most of the strength of our brand."

Sharp choices

Traditions are highly valued at the company. But innovation has been in its blood just as much since 1653. Says Schouten, "We are constantly looking for product innovations, drawing inspiration from history. And because an innovative company is often imitated, it is essential for us that our trademark rights are well protected. V.O. has been supporting us in this for years."

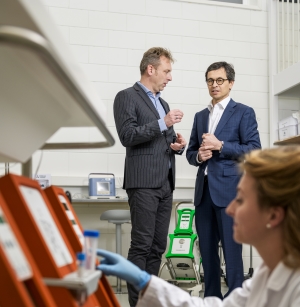

Raquel Alvarez is European trademark and design attorney at V.O.: "We manage the IP portfolio and advise on their trademark registration policy. We recently tightened the trademark policy in good consultation. As a result, there is now a strong strategy that provides good protection for all business activities."

Schouten: "You have to make sharp choices here, as a relatively small company. After all, maintaining trademarks costs a lot of money. That is why we do not register every collection and protect the most important: our word mark 'Royal Delft' and the logos for Royal Delft and the Porceleyne Fles with the initials 'JT' of Joost Thooft and the word 'Delft'."

Collaboration

Whereas Royal Delft's staff guarantee a subtle interplay between past and present, V.O.'s trademark attorneys and lawyers work together as a team for the client. "We see trademark advice, trademark monitoring and protection against infringement of our trademarks as one. It is logical and pleasant for us to find all of that at V.O.," Schouten says.

Trademark attorney Alvarez regularly collaborates with her attorney colleagues at V.O.: "Because I exchange information and developments about the client with our attorney and vice versa, we can give better advice. And our service with which we monitor trademarks is, of course, the vestibule of any litigation that our lawyers then pick up." Lawyer at V.O. Annelies de Bosch Kemper assists Royal Delft in cases of infringement of intellectual property rights: "That mutual cooperation is self-evident. When Raquel cleaned up the trademark portfolio, we sparred on this together. At such times it is important that she hears from me what scores in court." Schouten, Royal Delft, is satisfied: "The result of the recent action against infringement was more than positive. Not only was the trade in counterfeiting stopped, it even led to collaborations with new partners. We wouldn't have managed that without V.O. itself. That stays with you."

History

The craft of glazing and painting pottery was wildly popular around 1695. Around 1800 there was a downturn in the pottery industry, due in part to competition from the English Wedgwood, the discovery of porcelain clay and consequently the rise of the European porcelain industry. 'De Porceleyne Fles' kept its head above water and around 1840 was the only remaining pottery factory in Delft and its surroundings. In 1876, a Delft resident engineer, Joost Thooft, bought the factory. He wanted to restore the old tradition, the manufacture of blue 'Delfts'. He did so by innovating. He found the solution by using a composition of raw materials, which resembled the white hard English earthenware. Together with his partner Abel Labouchere, he succeeded in making a product that gained a good name all over the world. In 1904, the company was converted into a limited liability company.

As a token of appreciation for what the company has done since 1876 to preserve and revive the name of Delft and that of the ceramic industry in general, the right to use the predicate "Royal"/"Royal" was obtained in 1919.